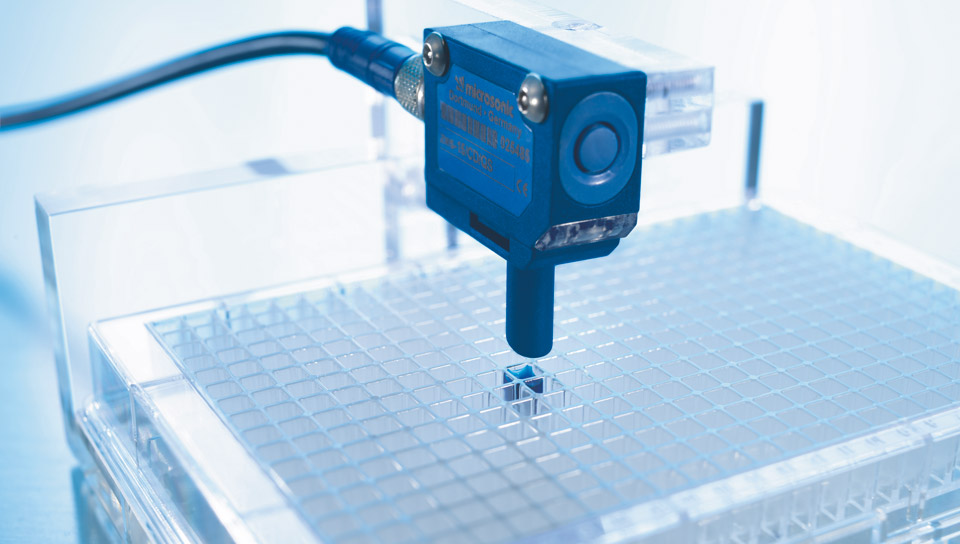

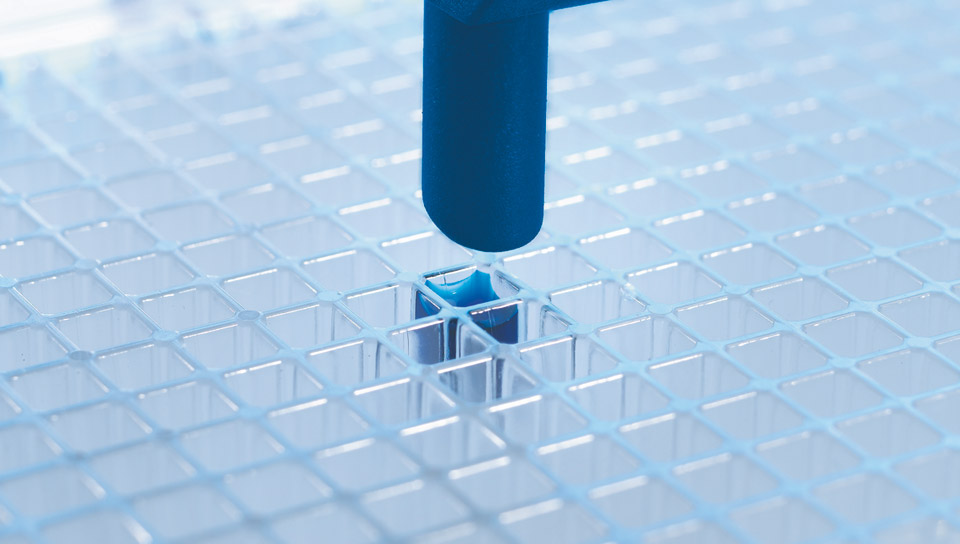

The miniature sensor housing

of the zws-15 has dimensions of 20 mm x 32 mm x 12 mm. The housing’s design and mounting is compatible with many optical sensors. This facilitates the conversion to ultrasonic sensors for critical applications.

For the zws sensor range

2 output versions and 6 detection ranges are available:

|

1 switching output, optionally in pnp or npn circuitry |

|

1 analogue output 4–20 mA or 0–10 V |

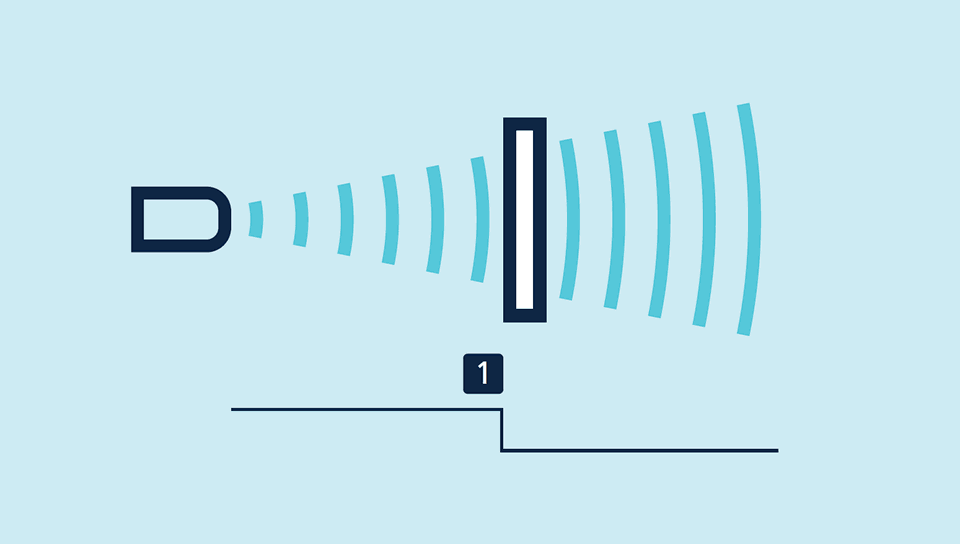

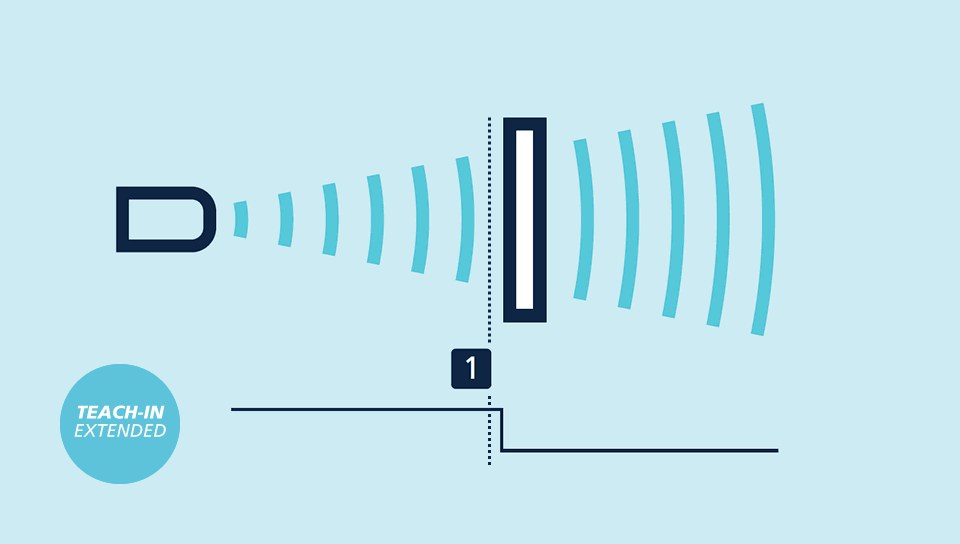

The Teach-in button

on the top facilitates the convenient setting of the sensor.

Two LEDs

in the sensor housing’s upper half indicate the switching output and respectively the analogue output states.

The temperature compensation of the analogue sensors

profits from a significant improvement. The sensors reach their operating point only 45 seconds after switching on operating voltage.