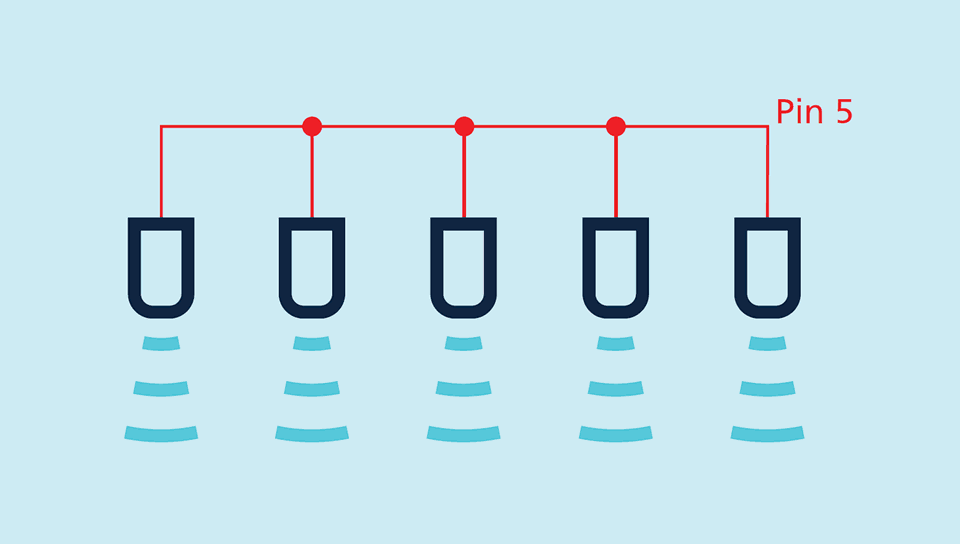

The pico+ ultrasonic sensors

are a compact series with M18 threaded sleeves and a housing length of only 41 mm. In addition to the variants with an axial beam direction, there is also a housing variant with a 90° angled head and radial beam direction.

With four detection ranges from 20 mm to 1.3 m and three different output stages, this sensor family covers a wide range of applications.

Sensors with the Push-Pull output stage support SIO and IO link modes. Sensors with analogue output are optionally available with 4–20 mA current output or 0–10 V voltage output.

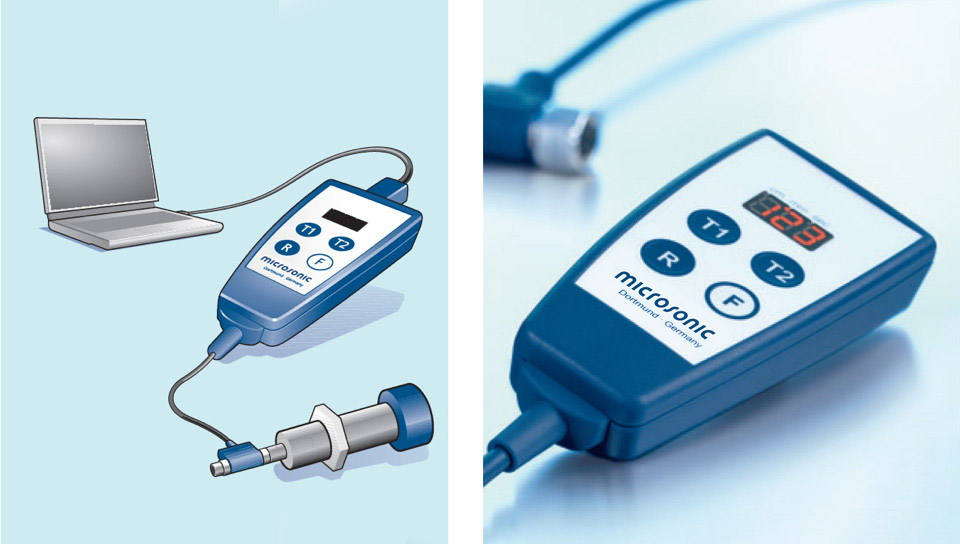

In SIO mode, sensors are configured using the microsonic Teach-in procedure on pin 5.

The sensors are Listed to applicable UL Standards and requirements by UL for Canada and the US.

Two dual colour LEDs

For the pico+ sensor family

there are 2 output stages and 4 detection ranges available:

|

1 Push-Pull switching output with pnp or npn switching technology with IO-Link interface |

|

1 analogue output 4–20 mA or 0–10 V |

Sensors with switching output have three operating modes:

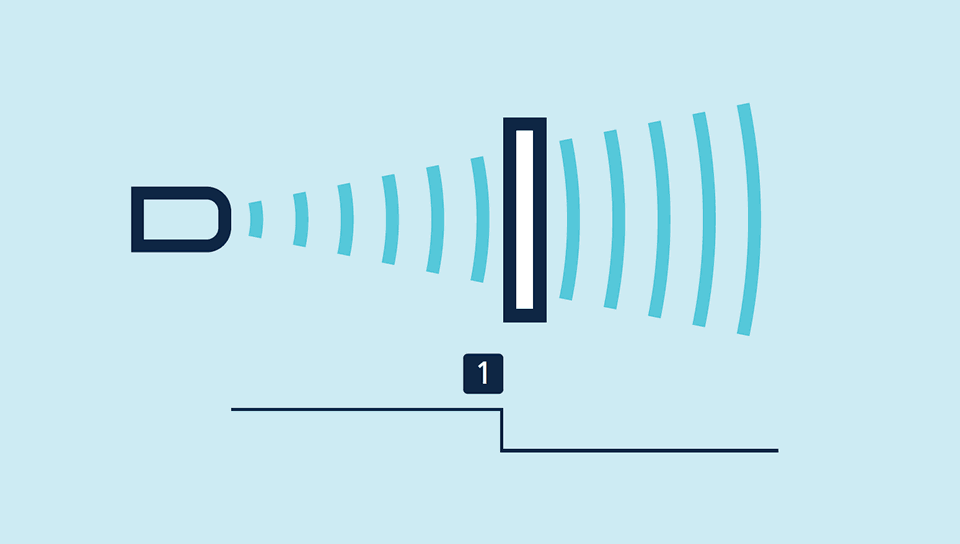

- Single switching point

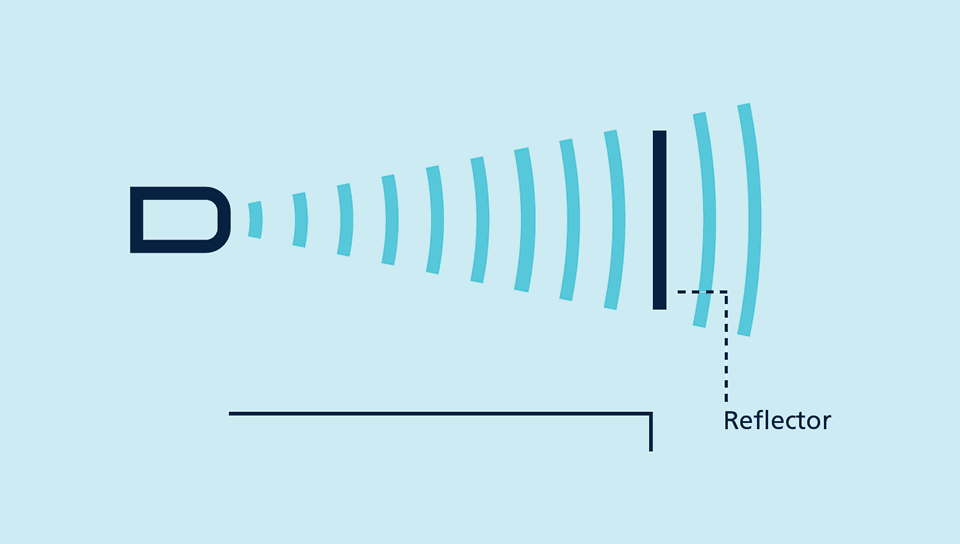

- Two-way reflective barrier

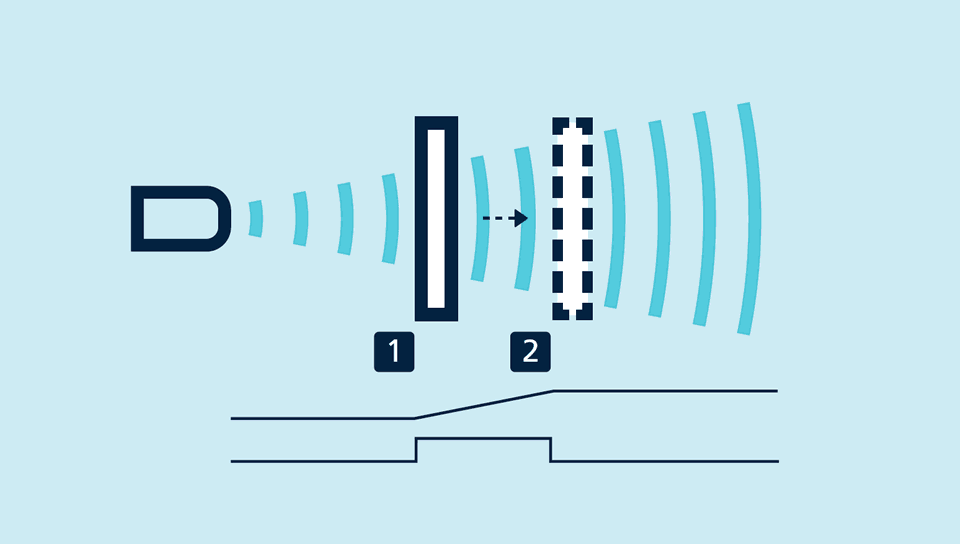

- Window mode

Teach-in of a single switching point

- Place object to be detected (1) at the desired distance

- Apply +UB to pin 5 for about 3 seconds

- Then apply +UB to pin 5 again for about 1 seconds