The dbk+5 ultrasonic double-sheet control

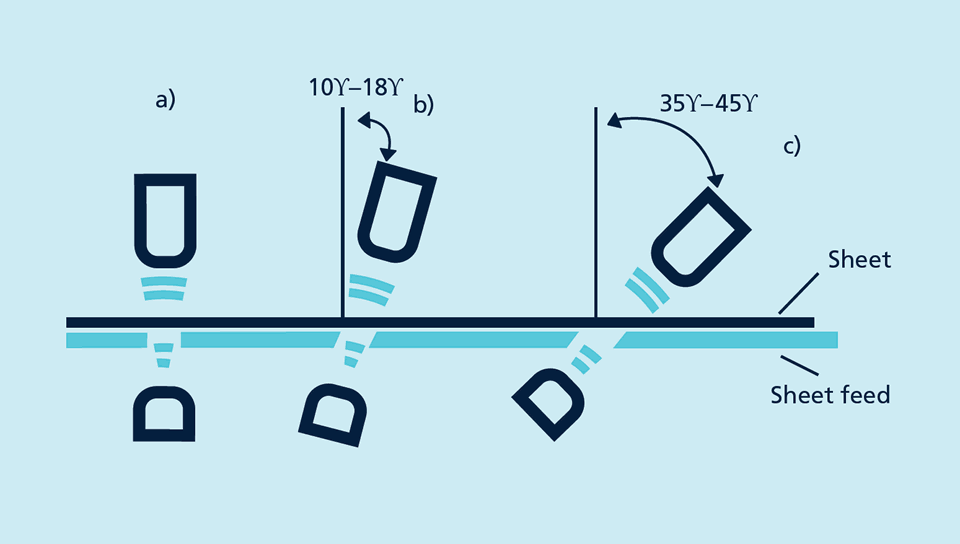

is designed for scanning thin sheet metal, plastic sheets and corrugated cardboard with thicknesses exceeding the working range of the dbk+4 sensors. The principle behind the operation is the same as for the dbk+4 sensors. The main difference between the systems lies in the materials to the detected. (For further information, see dbk+4.)