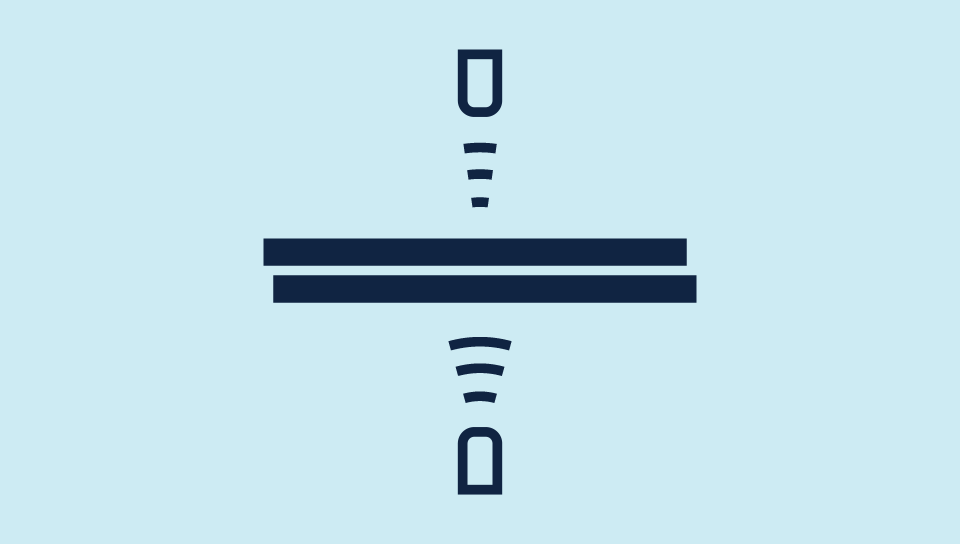

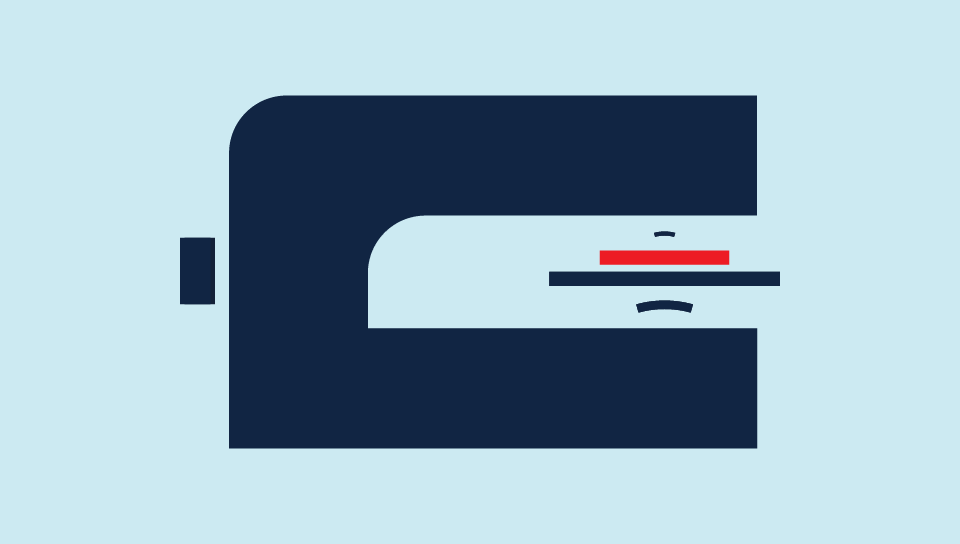

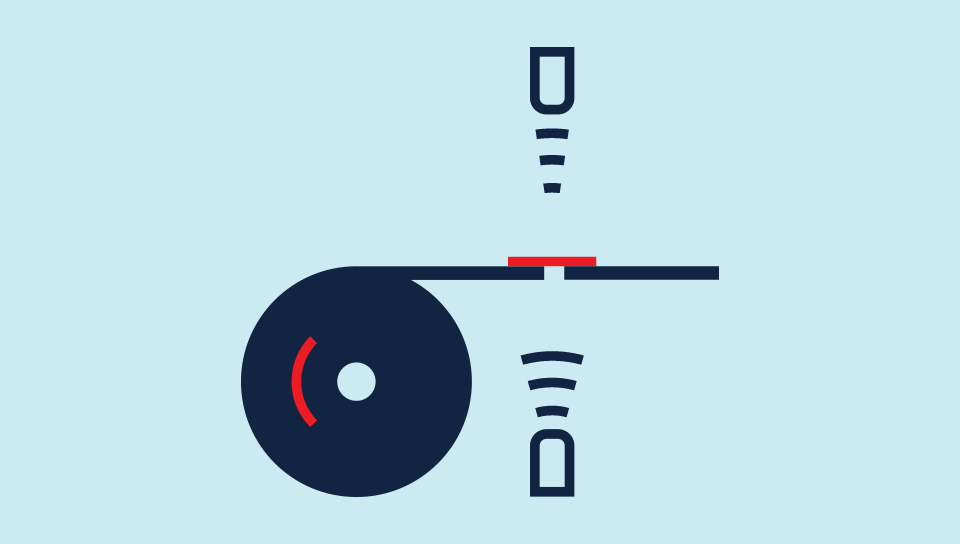

If the transmitter and receiver are arranged opposite each other as an ultrasonic barrier, thin material such as papers, foils, metal sheets can be "sounded through". It is possible with these dual-head sensors to detect double layers of material very easily and reliably.

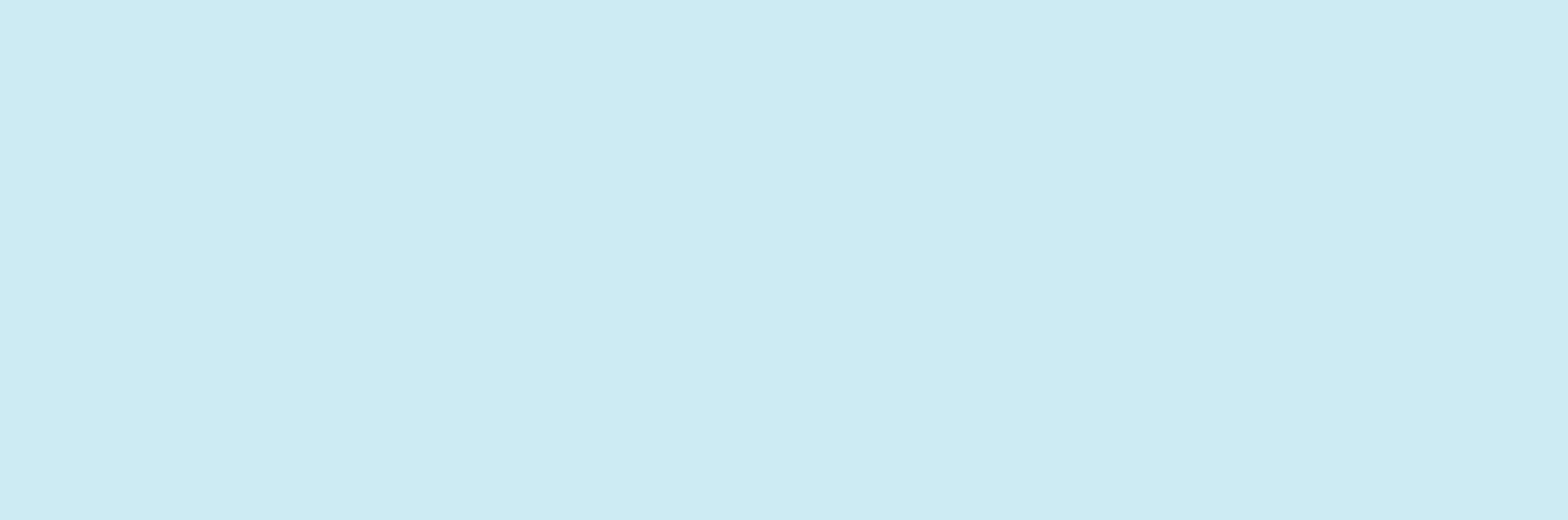

The functional principle:

The transmitter sends a high-frequency sound pulse. This propagates through the air at the speed of sound.

If the sound pulse hits a material, it is set into vibration and "sounded through". The receiver receives the signal. From the strength of the incoming signal, the ultrasonic sensor detects an additional layer of material.